FUVALVE(XIAMEN) CO.,LTD

TEL:0592-8930516

FAX:0592-3780866

E-mail:sales@ceramic-valves.com

Erosion resistant ceramic lined butterfly valve

Fuvalve offered 6″,8″,10″12″,14″ ceramic lined butterfly valves to a famous mining industry in Phillipine for acidic, high temp. and pressurize nickel slurry.Each size were used for seveal different applications with acidic and high erosion medium,the end user has test our product compare to the existing butterfly valve which they used to use and found the erosion-resistant property of Fuvalve ceramic lined butterfly valve are very excellent and quality are Satisfactory compare to other brand’s butterfly valve for monthes continuous operation as testing.

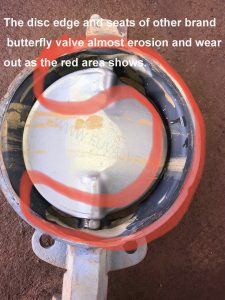

Below photos showing that the Fuvalve ceramic lined butterfly compared to other butterfly valve after monthes used.You’ll found the disc and seat of other brand butterfly valve were wear-out,but Fuvalve ceramic lined butterfly valve only the stem disc erosion but it still can last 3 monthes at least for this high-erosion applicaiton.

Typical Applications:

For most mediums which contains solid particles, abrasion is a very troublesome problem for valves and pipe fittings. Butterfly valve is one of the most common valve types in pipelines. If working medium is abrasive, service life of both soft sealing and metal sealing butterfly valves is very short. To solve this problem, Fuvalve developes full lined ceramic butterfly valve to meet the requirements of high abrasive applications. If working medium is both abrasive and corrosive, we can select suitable body materials for lug ceramic butterfly valves to avoid possible corrosion.

-Mining slag

– Coal washing

– Ash Slurry

– Suspension

– Ash

– Grain

– Quartz Sand

– Metallurgical dust

– Ores

– Granules

Erosion resistant ceramic lined butterfly valve

Design Features:

Product type

1.Ceramic butterfly valves are light and easy to install.